Hex Cap Screws

US Standard Inches

US Standard Inches

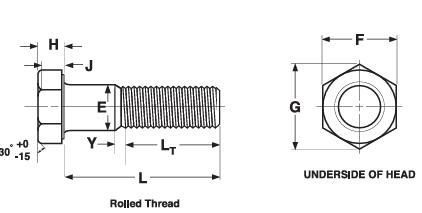

Hex Head Cap Screws have hexagonal heads and machine threads for use in a tapped hole or with a nut. They are generally used in applications where tight tolerances are required. The most common grades for Inch Hex Head Cap Screws include 2, 5 and 8.

| F | G | H | Lt | ||

|---|---|---|---|---|---|

| Size | Width Across Flats | Width Across Corners Max | Head Height | Thread Length | |

| 6" and shorter | Over 6" | ||||

| 1/4 | 7/16 | 0.505 | 5/32 | 0.750 | 1.000 |

| 5/16 | 1/2 | 0.577 | 13/64 | 0.875 | 1.125 |

| 3/8 | 9/16 | 0.650 | 15/64 | 1.000 | 1.250 |

| 7/16 | 5/8 | 0.722 | 9/32 | 1.125 | 1.375 |

| 1/2 | 3/4 | 0.866 | 5/16 | 1.250 | 1.500 |

| 6/16 | 13/16 | 0.938 | 23/64 | 1.375 | 1.625 |

| 5/8 | 15/16 | 1.083 | 25/64 | 1.500 | 1.750 |

| 3/4 | 1 1/8 | 1.299 | 15/32 | 1.750 | 2.000 |

| 7/8 | 1 5/16 | 1.516 | 35/64 | 2.000 | 2.250 |

| 1 | 1 1/2 | 1.732 | 39/64 | 2.250 | 2.500 |

| 1 1/8 | 1 11/16 | 1.949 | 11/16 | 2.500 | 2.750 |

| 1 1/4 | 1 7/8 | 2.165 | 25/32 | 2.750 | 3.000 |

| 1 1/2 | 2 1/4 | 2.598 | 15/16 | 3.250 | 3.500 |

Grade 2 Hex Head Cap Screws

Grade 2 Hex Cap Screws are made from low or medium-carbon steel. They’re typically used for economical and non-critical applications where the fastener is not subject to extreme temperatures or stress.

Grade 5 Hex Head Cap Screws

Grade 5 Hex Head Cap Screws are made of medium carbon steel and are heat-treated. Because of this, they’re stronger than Grade 2 screws.

| Core Hardness |

1/4 thru 1" diameter: Rockwell C25-C34 1-1/8 thru 1-1/2" diameter: Rockwell C19-C30 |

| Surface Hardness |

1/4 thru 1" diameter: Rockwell 30N54 max. 1-1/8 thru 1-1/2" diameter: Rockwell 30N50 max. |

| Proof Load |

1/4 thru 1" diameter: 85,000 psi 1-1/8 thru 1-1/2" diameter: 74,000 psi |

| Yield Strength |

1/4 thru 1" diameter: 92,000 psi min. 1-1/8 thru 1-1/2" diameter: 81,000 psi min. |

| Tensile Strength |

1/4 thru 1" diameter: 120,000 psi min. 1-1/8 thru 1-1/2" diameter: 105,000 psi min. |

| Elongation | 14% minimum |

| Reduction of Area Core Hardness | 35% minimum |

Grade 8 Hex Head Cap Screws

Grade 8 Hex Head Cap Screws are manufactured from medium carbon steel and are heat-treated. Grade 8 screws have higher tensile strength than Grade 5 screws. They are designed for use in high-stress applications.

| Core Hardness | 1/4 thru 1-1/2 diameter: Rockwell C33-C39 |

| Surface Hardness | 1/4 thru 1-1/2 " diameter: Rockwell 30N58.6 maximum |

| Proof Load | 1/4 thru 1-1/2 diameter: 120,000 psi |

| Yield Strength | 1/4 thru 1-1/2 diameter: 130,000 psi min. |

| Tensile Strength | 1/4 thru 1-1/2 diameter: 150,000 psi min. |

| Elongation | 12% minimum |

| Reduction of Area | 35% minimum |

Stainless Steel Hex Head Cap Screws

| Applications/Advantages | 18-8 | Used in products that require general atmospheric corrosion resistance, such as chemical and food-processing equipment. Some chemical environments may require special corrosion-resistant materials and precautions. |

|---|---|---|

| 316 | The molybdenum content gives this type of stainless steel even greater corrosion resistance than 18-8, as well as superior strength at high temperatures. | |

| Material | 18-8 | Cap screws are made from one of the following austenitic alloys: 303, 303Se, 304, XM7, all of which are characterized as having a chromium content of 17-19% and nickel content of 8-10%. |

| 316 | Cap screws are made from 316 stainless steel, an austenitic alloy which differs from 18-8 by its molybdenum content (2-3%) and a higher nickel content (10-14%). | |

| Hardness |

1/4 thru 5/8 diameter: Rockwell B95-C32 3/4 thru 1 diameter: Rockwell B80-C32 |

|

| Tensile Strength |

1/4 thru 5/8 dia, 2.25D and longer: 100,000-150,000psi 3/4 (2.25D & longer) & 7/8 thru 1 dia (3D & longer): 85-000-14,000pcs |

|

L9® Hex Head Cap Screws

Grade L9® screws have 9 engineering design features that make them the “world’s strongest and safest fastening system for the world’s toughest industry.”

L9® screws feature:

- Collared L9® prevailing torque meta locknut for assemblies subject to vibration

- Thicker-than-standard nut side walls to facilitate wrenching

- Heat treating to help prevent splitting and stripping

- Chamfers to eliminate corner drag

- Smooth washer bearing surfaces that distribute loads uniformly and reduce brinneling

- Plated finish to assist torquing

- UNR-radiused root bolt thread to increase fatigue resistance by reducing the notch effect of conventional UN threads. The UNR thread radius is maintained into the thread runout at the junction of the thread to the shank.

- Countersunk washer I.D. to center the washer against the bolt head bearing surface during tightening

- Radius under bolt head that adds strength

- Washer face that eliminates corner drag

- Thicker-than-standard bolt head to add a wrenching surface

Our experts are standing by to help you acquire the fasteners you need for your organization’s next project. Request a quote today.