Pins

Industrial pins are a specialized class of low-cost, non-threaded metal fasteners that are typically used to permanently or temporarily secure or align components or equipment. While styles and materials vary depending on their uses, pins are versatile and often interchangeable.

Marshall Sales is your source for high-quality pins that meet or exceed ASME, ASTM, SAE, and DIN standards and your expectations. Click a button below to learn more about specific pins or keep scrolling for more information.

Cotter Pins

Cotter pins are split pins manufactured from half-round steel wire. They’re fastened after passing through a hole by bending both ends. These pins provide a simple, low-cost, and secure way to lock parts together.

Cotter pins are frequently used to secure:

- Clevis pins in hitch assemblies

- Axles on trailers or vehicles

- Machinery linkages

- Slotted nuts on bolts

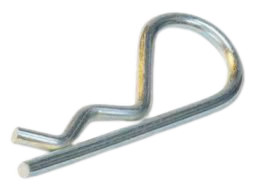

Hairpin Cotters

Hairpin cotters, often referred to as hitch pins or bridge pins, are frequently used as the mating part for clevis pins They are manufactured from spring wire or stainless steel.

Hairpin cotters are available in different wire diameters, overall lengths, and silhouettes, so it can be difficult to identify the exact size you need for any given project. Luckily, our experienced team is always ready to help.

They are used in a wide variety of applications, including:

- Connecting mechanical linkages in machinery

- Attaching components in suspension systems

- Securing hinges

- Joining parts in agricultural equipment and other machinery

- Rigging and lifting applications

- Furniture assembly

Clevis pins are cylindrical and non-threaded pins that feature a flat head and a through hole drilled into the opposite end. Typically, a cotter pin or hairpin cotter is inserted through this hole to secure a clevis pin in place. Clevis pins offer flexibility, which makes them ideal for applications that require movement or rotation. This is why they’re often used as quick and secure fasteners in many agricultural and industrial applications.

Clevis pins are often used to:

- Connect mechanical linkages in machinery

- Attach components in suspension systems

- Secure hinges

- Join parts in agricultural equipment and other machinery

- Secure rigging and lifting applications

- Assemble furniture

Clevis Pins

Dowel Pins

Dowel pins are cylindrical and solid with a chamfered end to make insertion easy. They are designed to achieve maximum holding power with increased shear strength to absorb lateral stress. They can be manually aligned with multiple workpieces, installed flush against a surface to produce a smooth result, or made to protrude beyond the workpiece to make it easier to align mating parts.

Marshall Sales supplies dowel pins in various finishes and materials to meet ASME B18.8.2, DIN 7, DIN 6325, and ISO 8734 standards.

Dowel pins are often used in:

- Locking devices

- Pivots

- Hinges

- Shafts

- Jigs

- Machinery fixtures

Roll Pins

Also known as spring pins or slotted pins, roll pins are hollow, cylindrical tube-style press-fit fasteners with chamfered ends. They weigh less and are easier to install than solid pins. Roll pins come in many types, materials, and finishes and are available in a wide range of stock options.

Roll pins are used as:

- Locking devices

- Positioning points

- Anti-chafing surfaces

- Shafts or sleeves for wiring

Taper Pins

Taper pins have a diameter that gradually decreases along the length. They’re designed to be inserted into a hole to create a secure and tight fit through friction. Taper pins are commonly used in various industries for accurate part alignment and fastening, especially in applications that require frequent disassembly and reassembly.

Taper pins are also available with an external or internal thread on one end. External threads are used when a tapered pin has to be removed from the driven (large) end. In these cases, tightening a nut on the threads will unseat the taper pin. The internal threads are used as anchors for leverage during removal.

Don’t see the pin you’re looking for in the list above? We also offer:

- Universal Clevis Pins with multiple drilled holes

- Cotterless Clevis Pins, which contain a detent ball instead of a drilled hole

- Hammerlock Cotter Pins

- Snap Pins

- Hitch Pins

- Groove Pins

- Coiled Roll Pins

- Hairpin Clips

Reach out to our team for more information on any of our pin products.